Ion Nitriding

Nitriding in glow discharge (ion nitriding) is an efficient method to increase hardness and wear-resistance of metals and alloys.

Servicing Southern Ontario

And beyond, from Guelph home.

Superior Hardening Process

Ion Nitriding Specialists!

Customer Care

We care about you & your project.

-

DEDICATED TO OUR CUSTOMERS AND ACHIEVING THE HIGHEST QUALITY & QUICKEST TURNAROUND TIMES

MPS offers reliable, high quality & productivity, a reliable process and top well-maintained machines to help you complete any project and finishing. MPS works and has strong relationships with manufacturers, service companies and distributors. We offer the best quality & technology in hardening for a variety of applications. Get top-notch results with MPS!

- Expert Knowledge in Surface Hardening

- Fast turnaround, competitive pricing

- Solid Technical Expertise

- Customer Driven Environment

-

TOOLS & MACHINE PARTS HAVE FAR HIGHER WEAR & CORROSION RESISTANCE

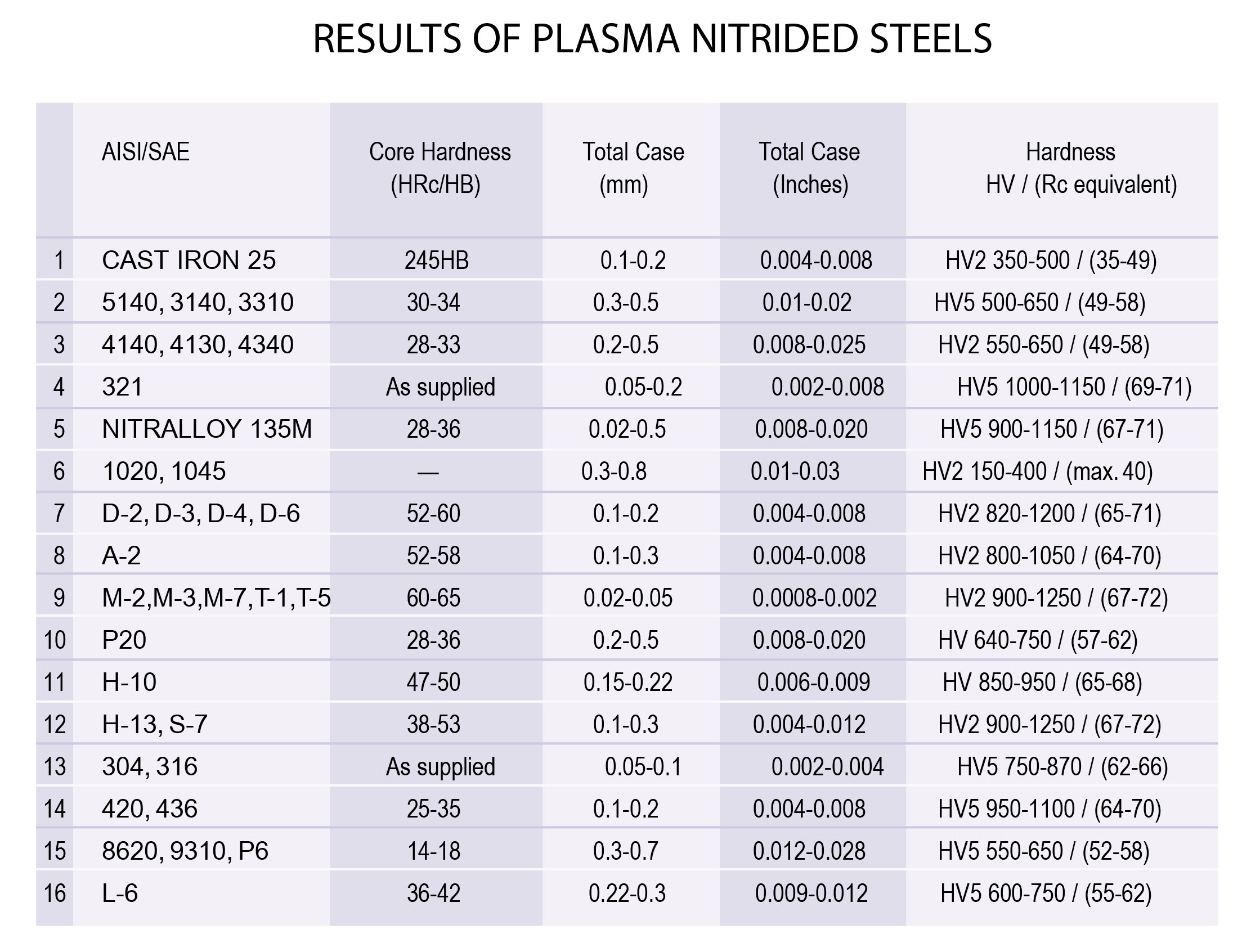

An efficient low-energy method Ion Plasma Nitriding achieves: Less distortions, wear-resistance, harder finishes, dense, non-porous, reproducible results, easy masking, excellent & clean working conditions, non-toxic and in accordance to environmental guidelines. - A thermochemical treatment which is carried out in a mixture of nitrogen, hydrogen and an optional carbon spending gas

-

Creating a compound layer free of diffusion is usually and ideally done before adding any PVD or CVD Coating as it increases hardness, is scuff resistant, there are less distortions and you can customize layers and other components. It is also commonly used when both hard and soft surfaces are required for parts. Common applications include:

- Gears

- Cylinders

- Extruder Screws

- Milling tools

- Drilling tools

Please contact us with your project inquiries and to set-up an appointment.

Testimonials

- “MPS is a very good company — quality orientated, fast turn around, and competitive prices.”

– “I’ve been working with MPS for more than 3 years and they have never missed a delivery date. I will gladly refer MPS to others.”

– “MPS is always helpful, in case of an emergency or rush job, for a small fee MPS will do what it takes to get it done. Excellent service!”

– “Our manufacturing line was down, and if we didn’t fix the problem overnight we would’ve missed the delivery of a project for a huge company, MPS worked through the night to get it done and helped us save our contract. Two thumbs up MPS!”